Work Plan

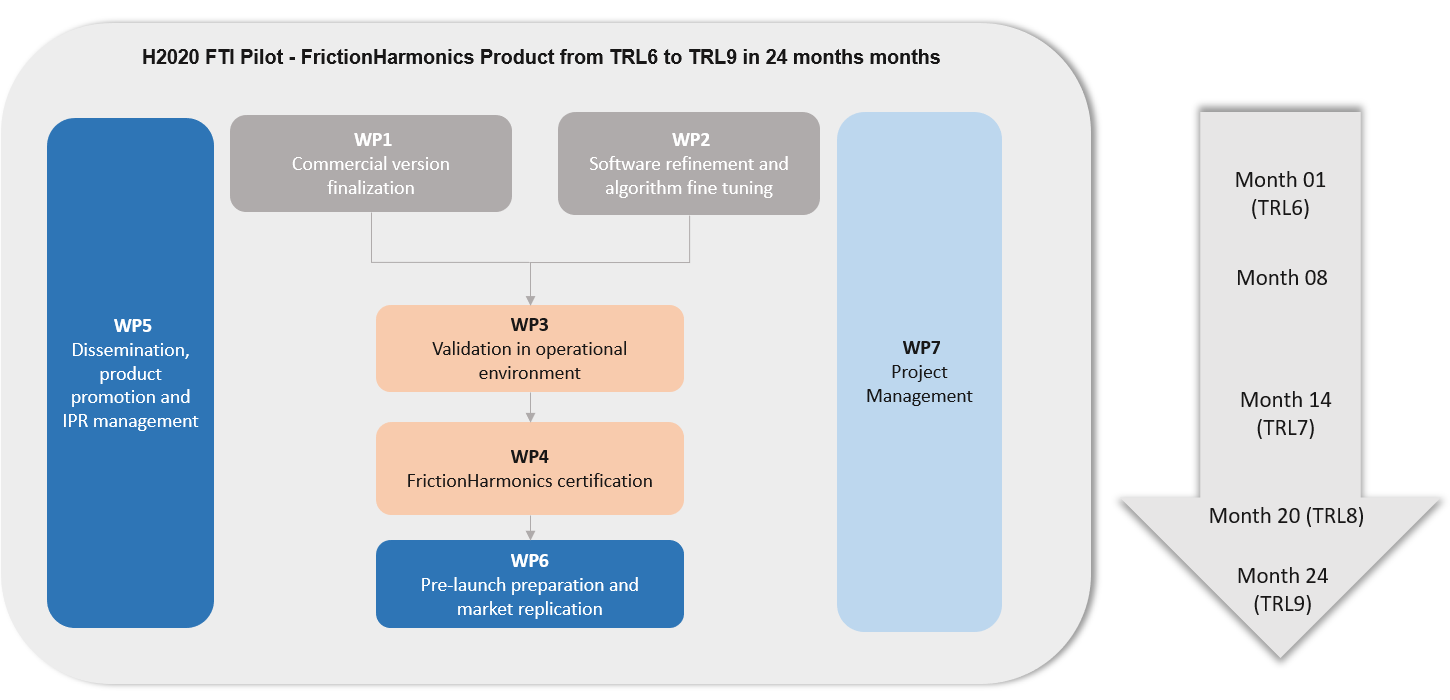

The activities scheduled during this action are organized into seven Work Packages (WPs). WPs 1-2 focus on the technical activities in order to refine the FrictionHarmonics system into a commercial product. WP3 includes the activities required to validate the smooth operation of FrictionHarmonics in operational environment (TRL7). WP4 pertains to obtaining the certifications required for our product to be fully marketable in Europe and USA. The dissemination, exploitation and IPR management activities will take place during WP5. WP6 is dedicated to pre-launch preparation including pre-commercial application and customer engagement that will facilitate a rapid and successful market take-up. Project management activities to ensure smooth progress of the action will take place as part of WP7. Figure 1 presents the Pert chart for the FrictionHarmonics action.

Figure 1: Work packages overview

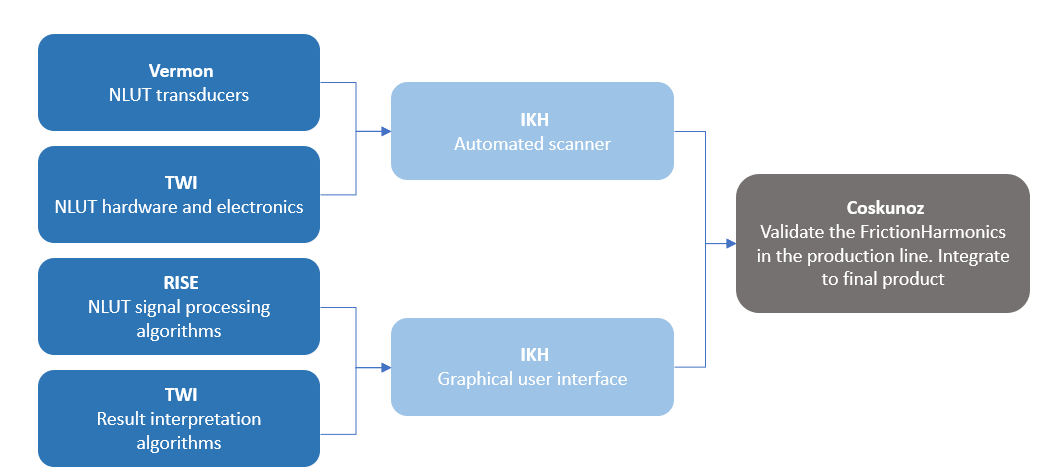

Our consortium is composed of 5 partners with strong complementary skills, strategically located in Northern, Central and Southern Europe. Our combined skill set guarantees a successful outcome for this action and our network span will ensure a rapid and successful FrictionHarmonics market take-up. Each partner’s role in the FrictionHarmonics action is illustrated in Figure 2.

Figure 2: FrictionHarmonics partner roles

RISE is the Swedish Research Institute and innovation partner. In international collaboration with industry, academia and the public sector, they ensure the competitiveness of the business community and contribute to a sustainable society. Their deep knowledge with respect to advanced signal processing algorithms to extract useful information from signals is the cornerstone of FrictionHarmonics. RISE will provide significant contribution in WP2 regarding the signal processing algorithm refinement as part of WP2.

IKH is high-tech company specializing in industrial Internet of Things, service robotics and data-driven intelligence. They possess strong expertise in the areas of next-gen automation and human machine interaction. Based on this, they are responsible for the automated scanner design optimization as well as the Graphical User Interface enhancement (WP2). They will also lead WP5 leveraging their experience in digital content delivery.

Vermon has been leading 1-3 piezoelectric composite technology development and industrialization to enhance ultrasound transducers state of the art for more than 15 years. Their experience with transducer design is crucial for the FrictionHarmonics application. Vermon will be the coordinators of the action. They will lead the commercial system finalization (WP1) and they will also greatly help with the dissemination and pre-launch preparation (WP5, WP6) leveraging their global network of clients.

TWI is a world-class Research Institute with presence in multiple areas specializing in material joining and structural integrity applications. TWI originally invented the FSW process and has over 20 years of experience of working on the joining of a wide variety of materials, thicknesses and joint configurations using this process. The continuing development of FSW tools and welding techniques keeps TWI at the leading edge of process development for its Industrial Membership base. Over the last 70 years TWI has accumulated a wealth of knowledge in the area of Non-Destructive Testing with ultrasonic methods focusing on the hardware electronics pulser/receiver design and development. TWI will work in WP1 with regards to hardware and electronics redesign, and in WP3 (validation in operational environment) leveraging their cutting-edge FSW facilities.

Coskunoz is a global leader in the development of customised solutions for the production of welding machines for the automotive and aerospace sectors. Serving the biggest names in the aerospace (Boeing) and automotive (Volkswagen and Renault) they are the ideal candidate to lead WP6, focussing on customer engagement and pre-launch preparations including distribution network establishment.