Basic Principles

It is difficult to detect kissing bonds using conventional NDT techniques, such as pulse-echo ultrasonics, because the resulting change in amplitude is often very small. Through extensive R&D activities we developed a non-linear ultrasonics technique customised for the inspection of kissing bonds in FS welds.

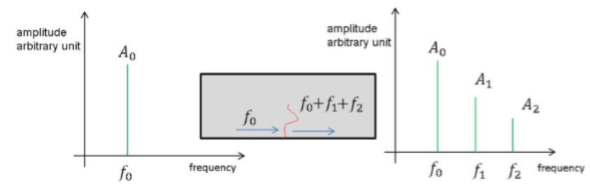

Our technique uses finite amplitude or acousto-elasticity to investigate defects in materials. The finite amplitude harmonics measures the acoustic harmonics generated by the interaction of the sound wave with nonlinearities in the material. If finite amplitude ultrasound passes through a region of non-linear properties, it generates higher order acoustic harmonics signals. The harmonic of the fundamental wave is generated when the mechanical wave interacts with an imperfect interface. Kissing bonds being very tight defects lead to “clapping and rubbing” when excited by the input signal; hence they generate higher harmonics of the input signal.

Figure 1 shows schematically the behaviour of the input pulse after interaction with a kissing bond defect.